for development

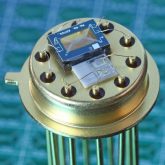

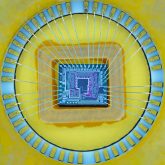

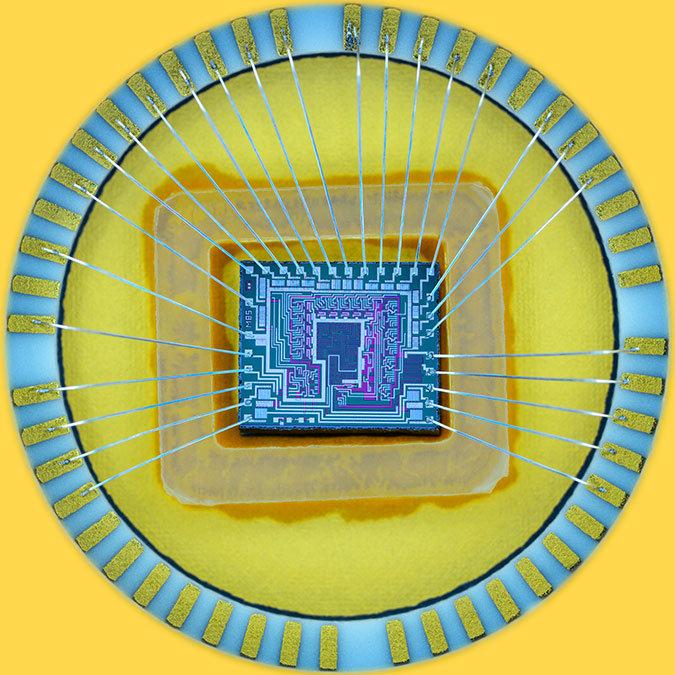

for development and production of microchips

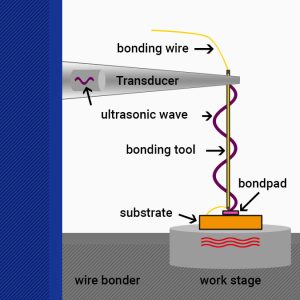

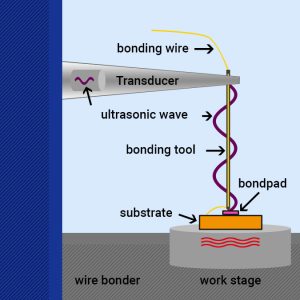

WIRE BONDER

WIRE BONDER

Overview Wire and Die Bonders

Overview Wire and Die Bonders

BONDING EXPERTS

BONDING EXPERTS

with motorized Z-Y-X axes

with motorized Z-Y-X axesand bond head rotation

AUTOMATIC WIRE BONDER

AUTOMATIC WIRE BONDER

with motorized

with motorizedZ- & Y- axes

HEAVY WIRE BONDER

HEAVY WIRE BONDER

for placing microchips

for placing microchips

DIE BONDER

DIE BONDER

in

Germany

for example at

World’s leading trade fair

for electronics development and production